MULTI-POINT INTERACTIVE CAPACITIVE TOUCH FOIL

The 11th generation Capacitive Touch Foil;size rangs from 32"to 84".

Product Numbers:GDT-RTP-LCD-C

Product description:RTP Touch LCD Modules(Optical Bonded)

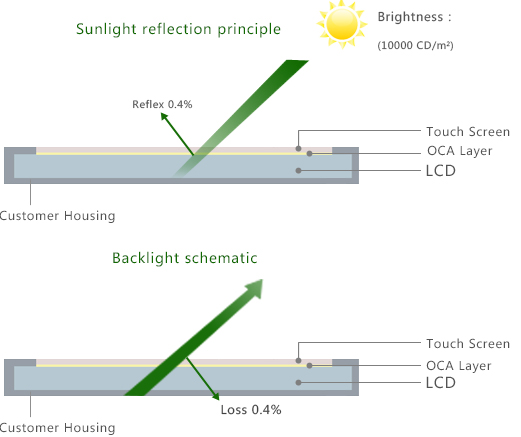

Benefits after optical bonding

1.Increase sunlight readability up to 400%;How to process the optical bonding ?

Step 1: Specimen (Verify technical feasibility)

Preparatory Work:

1.Drawings design; 2.TFT testing board kits: 2 set; 3.TFT&TP:5-10 pcs each;

4.Lead Time: 12-15 days

Step 2: Trial production (confirming quality standards)

Preparatory Work:

1.Improve the quality according to feedback;

2.Confirm quality standards;

3.Freeze cost and quality yield;

4.TFT&TP:50-200 pcs;

6.Lead Time: 18-25 days.

Step 3: Mass Production (stable mass production)

Preparatory Work:

1.TFT+PCAP:300-1000 pcs;

2.TFT testing board: 5 sets;

3.Lead Time: 25~35 days;