MULTI-POINT INTERACTIVE CAPACITIVE TOUCH FOIL

The 11th generation Capacitive Touch Foil;size rangs from 32"to 84".

Product Numbers:GDT-PCAP-LCM-C

Product description:Customize Your Touch LCM Panel Modules (4.3" to 32")

Customize Your Touch LCM Display Modules

From design and engineering to prototyping and production, GDT create your touchscreen display modules following your requests.

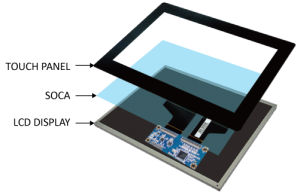

With a Evolution ITO touch panel and chip-on-board (COB) or chip-on-flex(COF) touch controller bonded to a commercial or Industrial grade LCD, All touch LCM display modules deliver reliability that help streamline your supply chain and simplify assembly.

1). LCD

Choose: An open spaces is offered to customers on choose LCD. Customer can specify the LCD brands and models based off their needs.

If open cell type LCD Panel used,information such as Resolution, Brightness, Temperature Range, Viewing Angle, Interface, are needed.

2). Touch Sensor

Choose: Touch sensor thick, FPC Tail position and size

3). Cover Glass

Choose: Custom sizes, shapes, edge treatments, holes and cut-outs, materials (strengthened glass, safety glass, IR/UV blocking glass for outdoor) Anti-glare anti-fingerprinting Anti-reflective surface treatments, Border (colors, logos, icons, IR transmissive windows)

4). Touch Controllers

Choose: Wide variety of touch IC’s. Performance tuning for water,gloves and touch keys, suitable for thick cover glass or overlays, other application specific tuning as requested.

5). Special Displays

Choose: Screen peep-proof protection, Anti-blue light eye protection, IR blockers, UV filters.

6). Bonding

Choose:Optical Bonding is prefered (Tape Bonding as options per customer request).

How to process the optical bonding ?

Step 1: Specimen (Verify technical feasibility)

Preparatory Work:

1.Drawings design; 2.TFT testing board kits: 2 set; 3.TFT&TP:5-10 pcs each; 4.Lead Time: 12-15 days

Step 2: Trial production (confirming quality standards)

Preparatory Work:

1.Improve the quality according to feedback;

2.Confirm quality standards;

3.Freeze cost and quality yield;

4.TFT&TP:50-200 pcs;

6.Lead Time: 18-25 days.

Step 3: Mass Production (stable mass production)

Preparatory Work:

1.TFT+PCAP:300-1000 pcs;

2.TFT testing board: 5 sets;

3.Lead Time: 25~35 days;